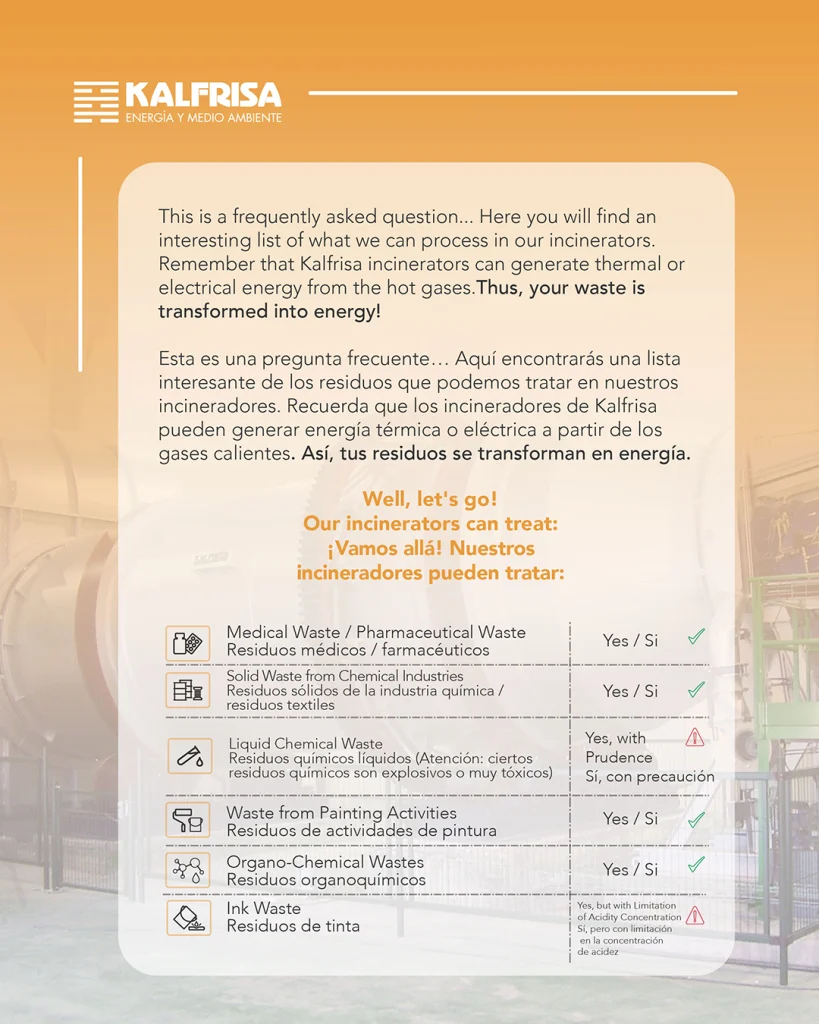

At Kalfrisa, we specialize in designing and installing technological solutions for thermal waste treatment and waste to energy. One of the most critical factors in ensuring the efficiency of these processes is the Lower Heating Value. Understanding this parameter allows us to maximize energy performance, optimize resources, and ensure compliance with environmental regulations.

In this post, we address several questions about why the heating value is key in waste-to-energy processes, how it is calculated, and which values should be considered to plan efficient waste management.

What is the calorific value of waste, and why is it important?

The lower heating value (LHV) indicates the amount of energy a waste material can release during combustion. This information is essential for defining:

- The design of the incinerator

- The capacity of the gas treatment system

- The potential for energy recovery

- The need (or not) for auxiliary fuel

For example, the minimum calorific value for waste to burn without additional fuel is between 12 and 14 MJ/kg, depending on its composition and moisture content.

How does the calorific value influence energy recovery?

In waste-to-energy facilities, a high calorific value allows:

- Generating more useful energy

- Reducing the consumption of fossil fuels

- Designing more efficient and sustainable systems

For example, a mixture of hazardous waste, medical waste, and PVC has an average calorific value of 22.4 MJ/kg, meaning it can be thermally valorized without the need for auxiliary fuel.

How is the lower heating value of a waste mixture calculated?

To estimate the calorific value of a waste stream, the following steps are followed:

- Identifying the materials that make up the waste

- Determining the individual calorific value of each component

- Applying a weighted average based on their proportion in the mixture

Kalfrisa: Experts in Energy Recovery Tailored to Each Type of Waste

Each waste stream has a different thermal behavior. At

Do you want to optimize the energy recovery of your waste?

At Kalfrisa, we help you design the most efficient solution based on the characteristics of your waste. Contact our engineering team for personalized advice.