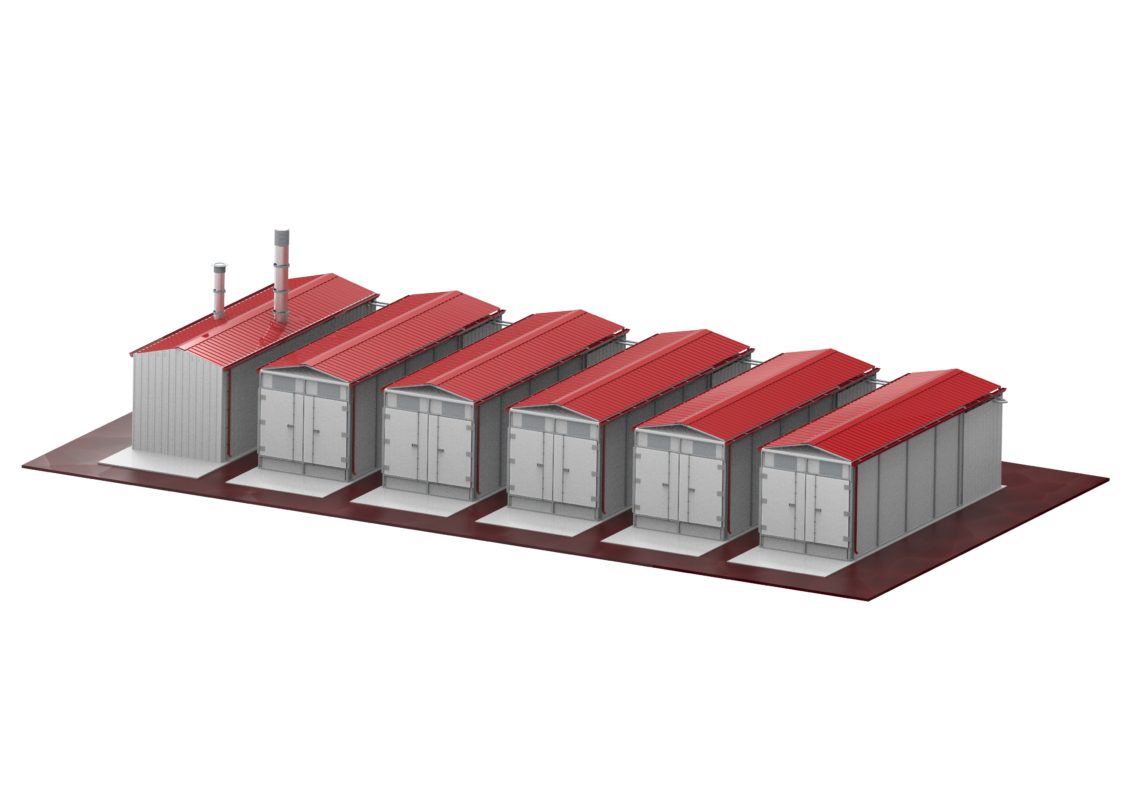

Biomass drying equipment

Kalfrisa remains in continuous research and development of its systems; International news is affecting us users in terms of energy and fuel costs. However, it is not only a cost issue, so is securing the fuel supply.

In certain regions of the world, we have encountered these problems in the past, which is why Kalfrisa already provided a solution to this issue over 5 years ago by designing centralized installations of biomass drying equipment (solid fuels).

Biomass centralization has 2 main advantages:

- It allows automate hot water production at a single point, lowering the operating cost of the process.

- Increases the performance of the installation; Depending on the simultaneity of the processes, a lower power boiler can be installed to adjust to the average consumption of the installation.

The centralized heat production room provides thermal energy to the installation. It is powered by biomass and in specific situations, due to lack of biomass supply or peak thermal consumption, the oil or gas boiler comes into operation.

Each consumption point of the installation has its own hot air generation unit; These units are fed by the hot water generated in the boiler room. The closed and completely isolated circuit allows to use only the necessary energy, recirculating the excess energy back to the boiler room.

The Kalfrisa proposal for drying with biomass allows a reduction of up to 90% in the consumption of fossil fuels;

Centralization allows the implementation of other renewable technologies such as:

- Waste recovery

- Photovoltaic solar energy

- Solar thermal energy

- Utilization of thermal remnants from other processes