PRODUCTS

Energy recovery

ENERGY RECOVERY

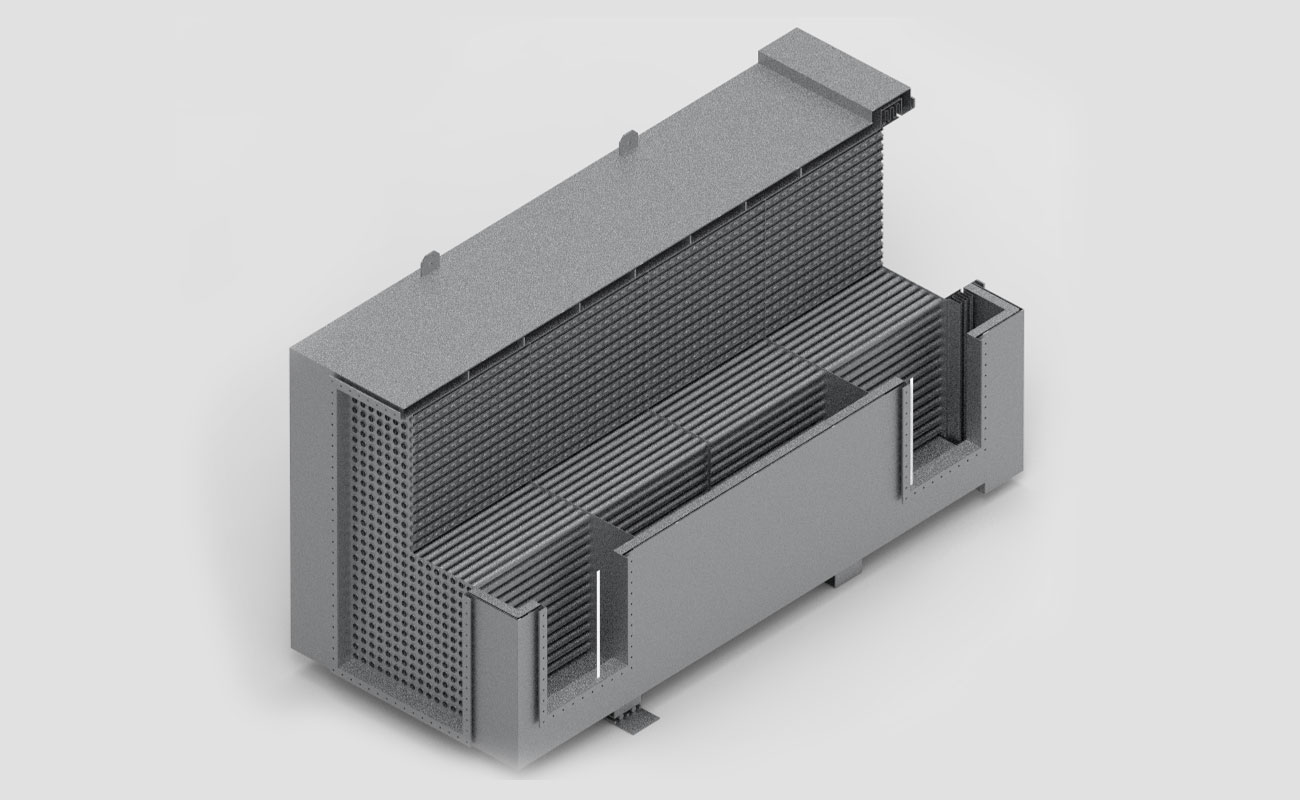

A heat recuperator absorbs a significant part of the thermal energy from the exhaust gases generated during the combustion of a solid, a liquid or a gas, used for melting, heating, roasting, drying, etc. a specific product. Absorbed thermal energy is transmitted to another fluid, usually the combustion air for the process itself. Fuel savings are so considerable that the exchanger cost can be amortised in a few months.

Heat recovery units can be installed in all flue gas exhaust ducts from a production process where combustion air is required.

ENERGY RECOVERY

Sectors

STEE INDUSTRY

- Reheating furnaces

- Forging furnaces

- Thermal treatment furnaces (annealing / stripping)

- Galvanising lines

- DRI modules for iron production plants

- Blast furnaces

GLASS INDUSTRY

- Melting furnaces

ENAMEL INDUSTRY

- Frit melting furnaces

ENERGY RECOVERY