MODULAR OR SPECIAL HEATERS

These heaters are especially suitable when working conditions (heating power, temperature increase, working pressure, etc.) exceed the limits established for compact series or semi-series devices.

They are large equipments which may include gas recirculation and which take up a rather considerable space. They are tailor designed according client requirements and may be installed in different layouts such as: linear, elbow or U-shaped.

MODULAR SYSTEM FORMED BY:

mixer + smoke recirculation + process gas exchanger.

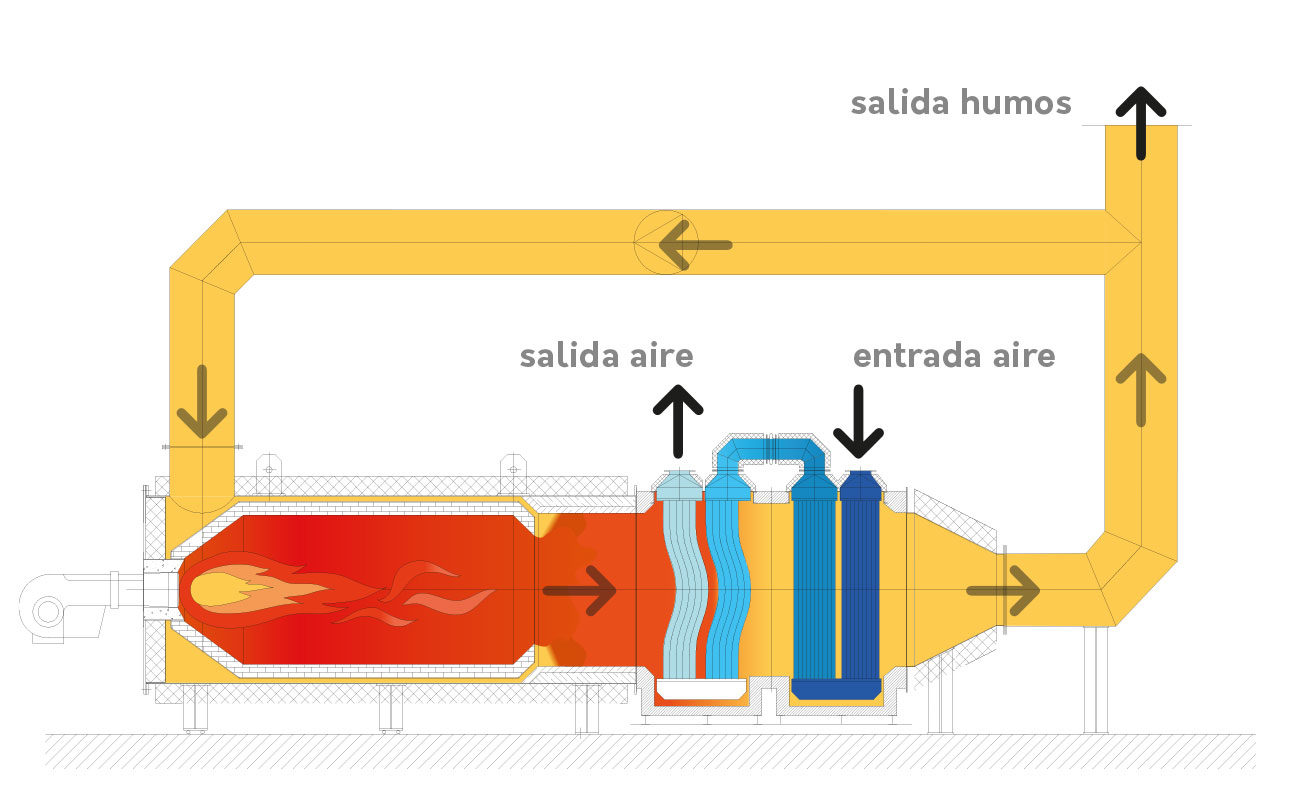

MODULAR SYSTEM FORMED BY:

combustion chamber + process gas exchanger.

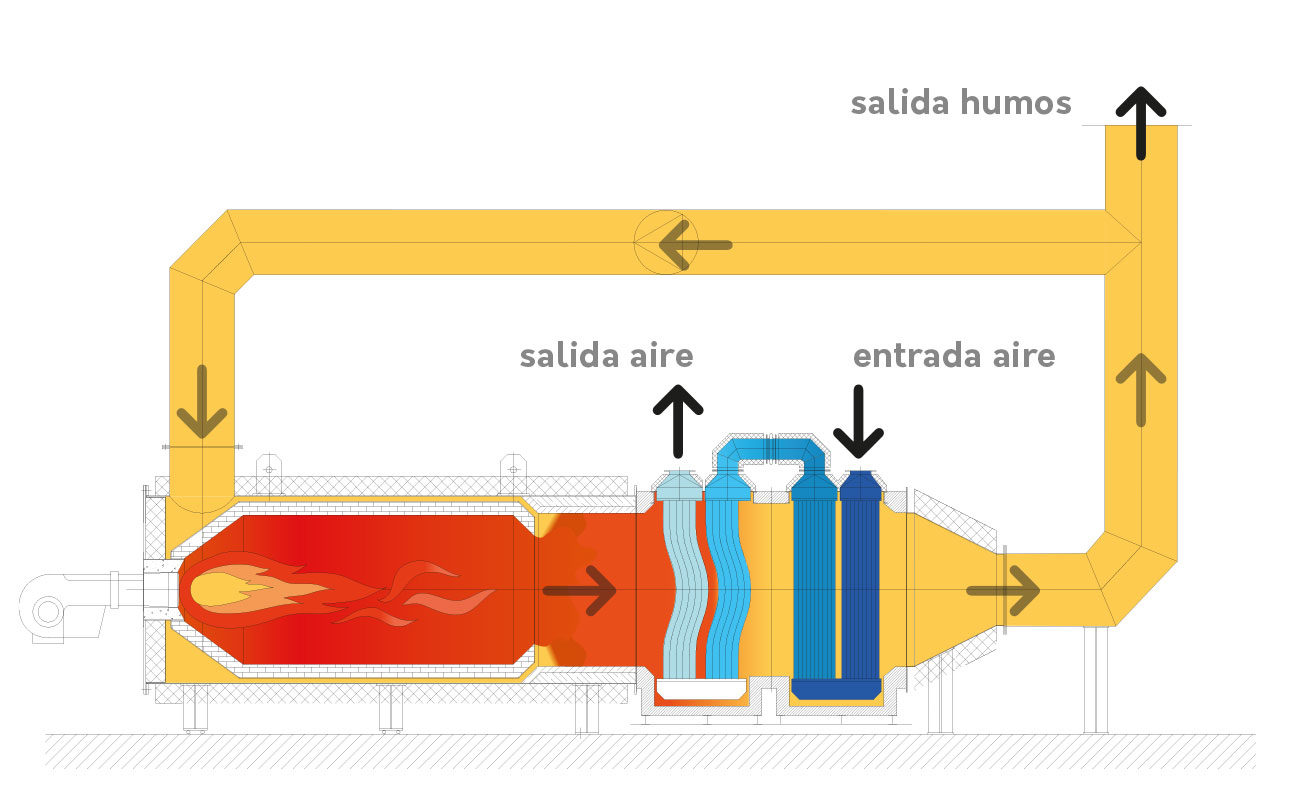

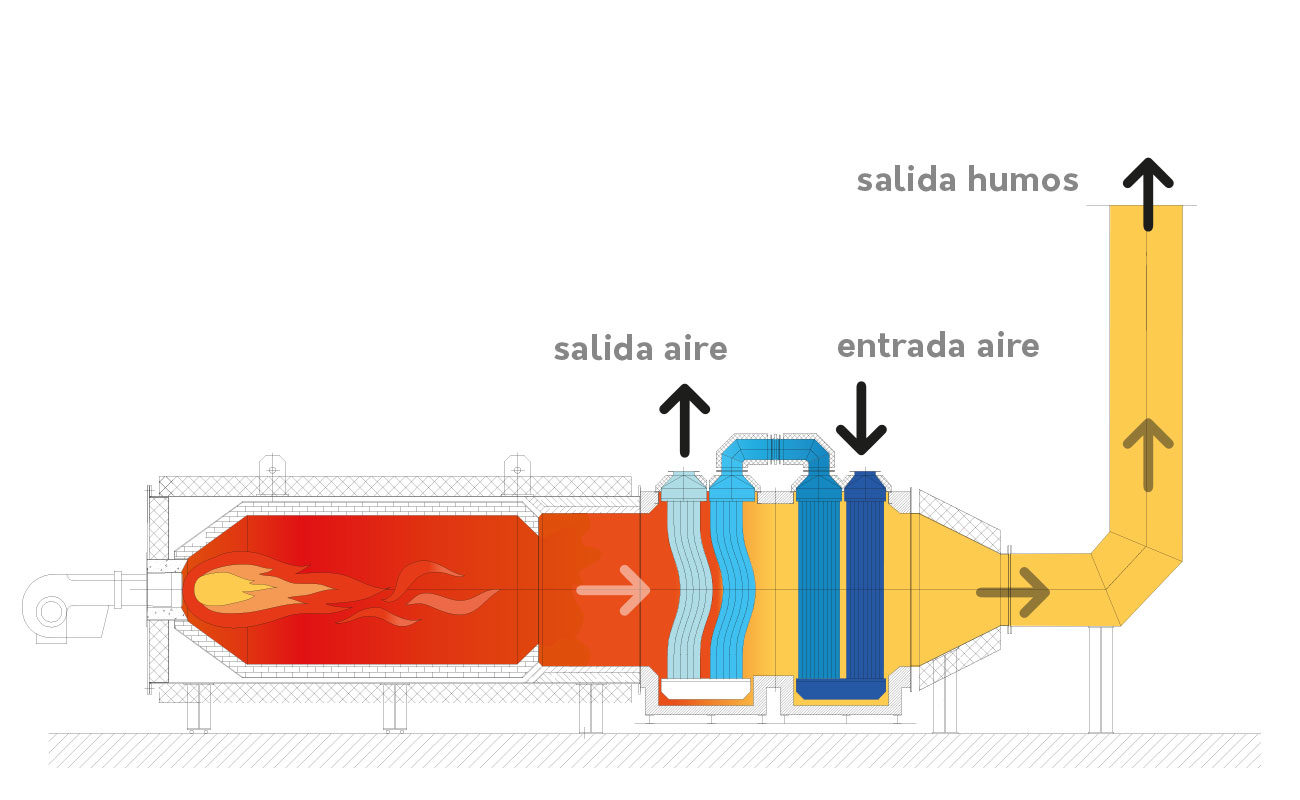

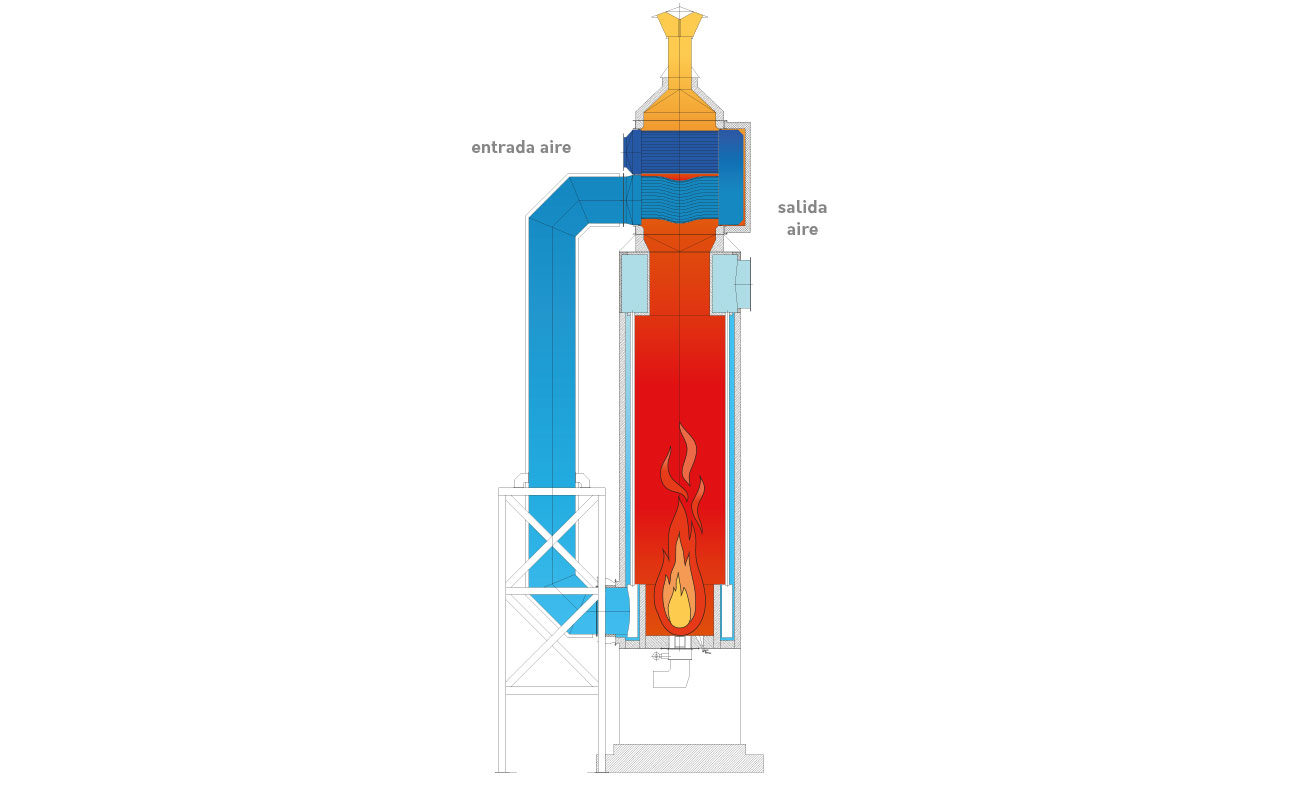

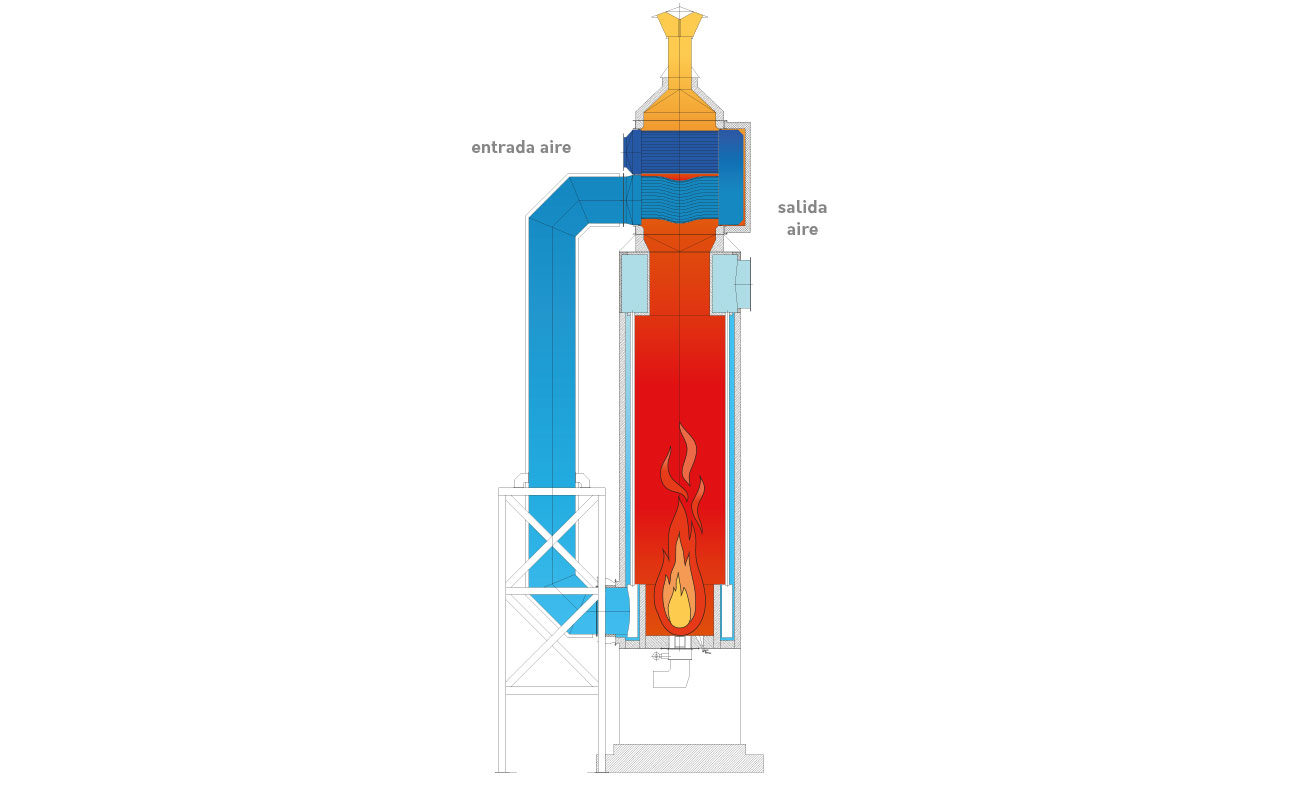

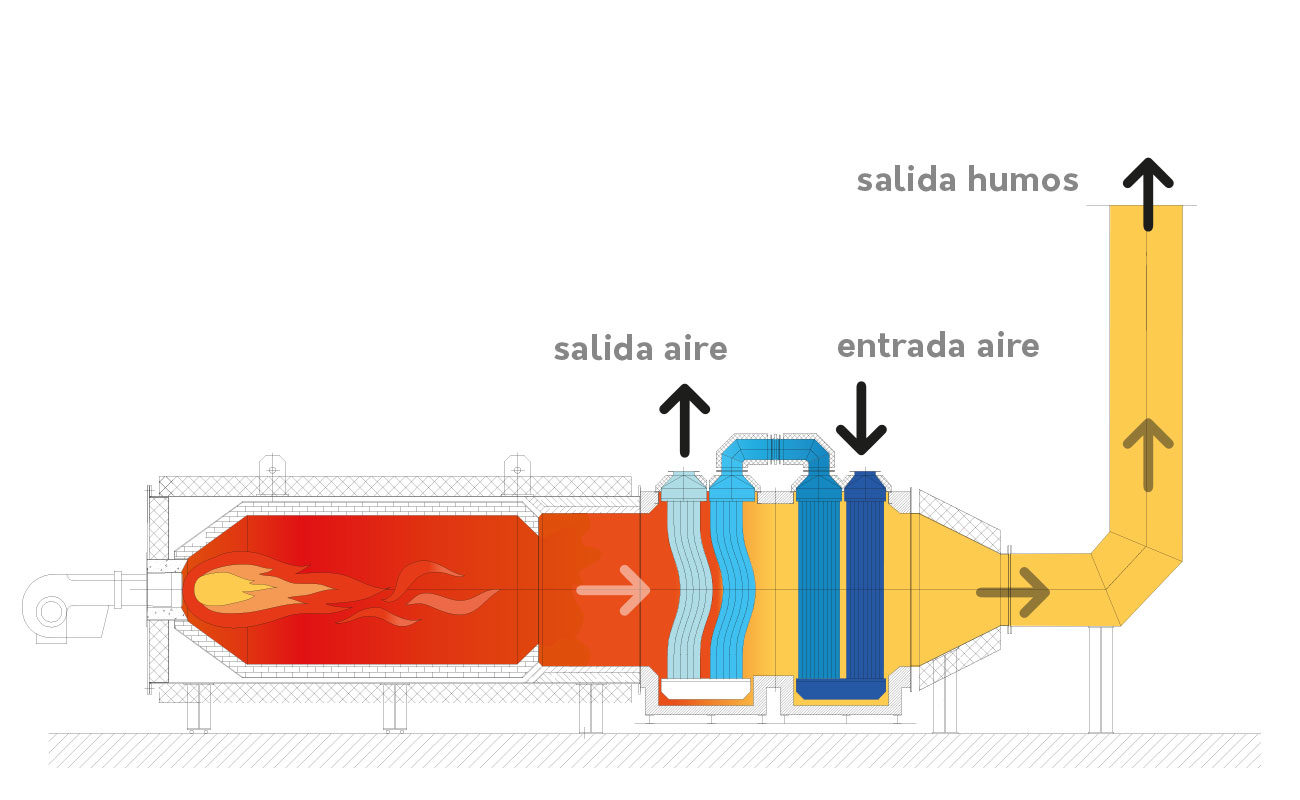

MODULAR SYSTEM FORMED BY:

radiation chamber + preheating of combustion air.

Fields of application

- Spray drying processes

- Mining sector

- Production of hot air for drying fishmeal.

Criteria for use

- Large thermal jump (delta T) for high flows

- Efficiency over 85% thanks to the incorporation of recirculation of gases.

- Capacity for heating air up to 700ºC.

- Systems designed for solutions with a very low level of NOx under 25 ppm.

- Capacity for continuous operation.

AIR HEATING