RADIATION RECUPERATORS

These recuperators transfer heat (thermal energy)between primary and secondary flows by radiation.

Jacketed radiation recuperators offer a reduction of 40% or more in fuel consumption. Their compact design facilitates its installation in the gas exhaust chimney.

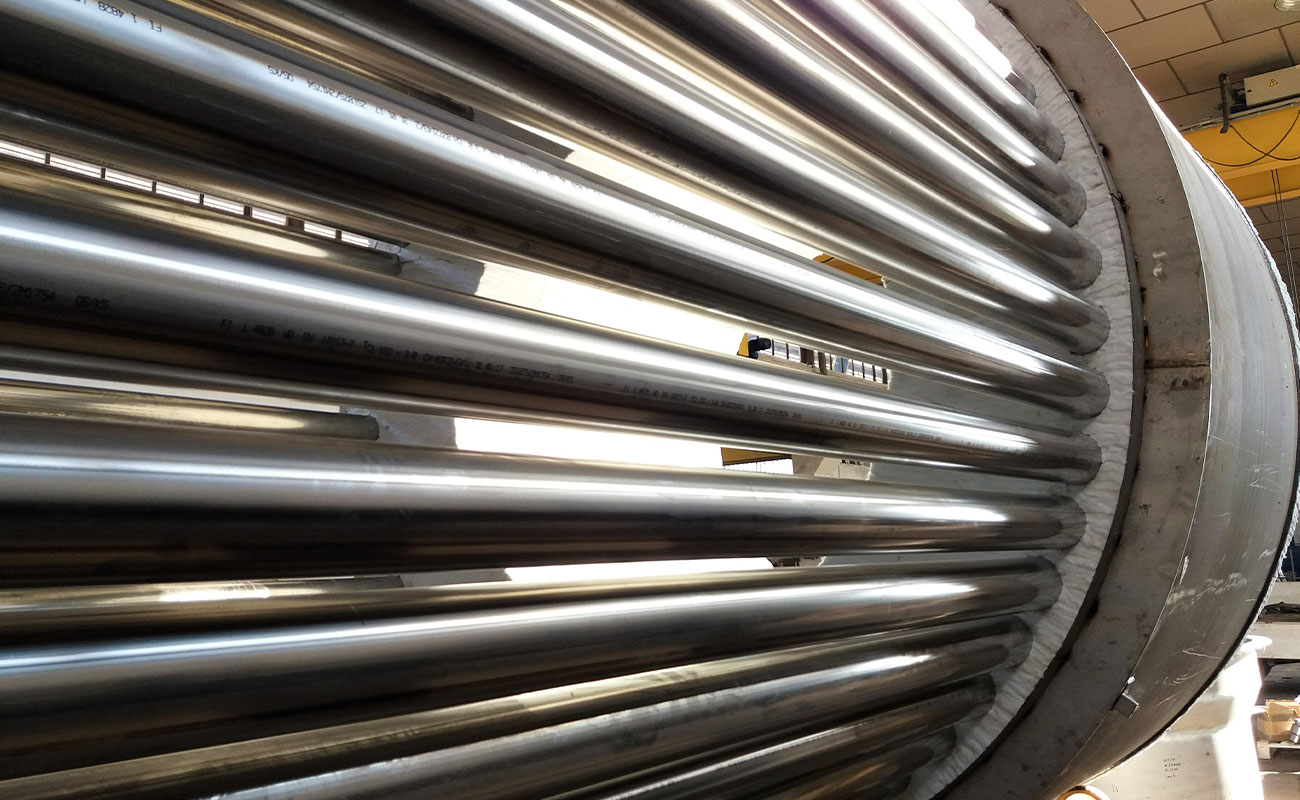

They are made of two concentric cylinders in which the secondary fluid circulates through a circular crown, either parallel to the recuperator axis or helically, in counter or in parallel flows. Suitable for working pressures up to 2000mm WG (water gauge).

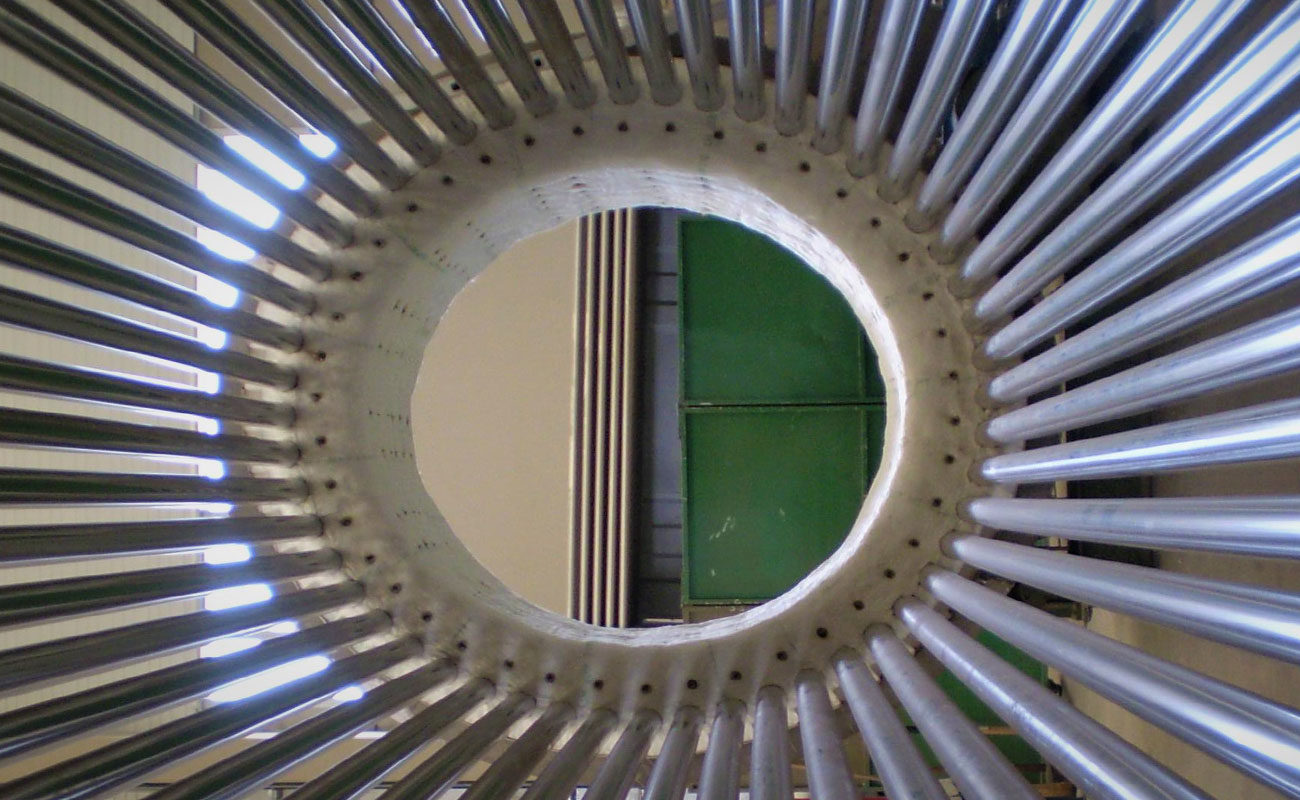

For higher working pressures, tube basket type recuperators offer better performance, greater resistance and a more homogeneous air distribution. They are designed replacing the inner shell with a tube basket with an annular layout, through which the air circulates, so the heat transfer continues to be carried out by radiation.

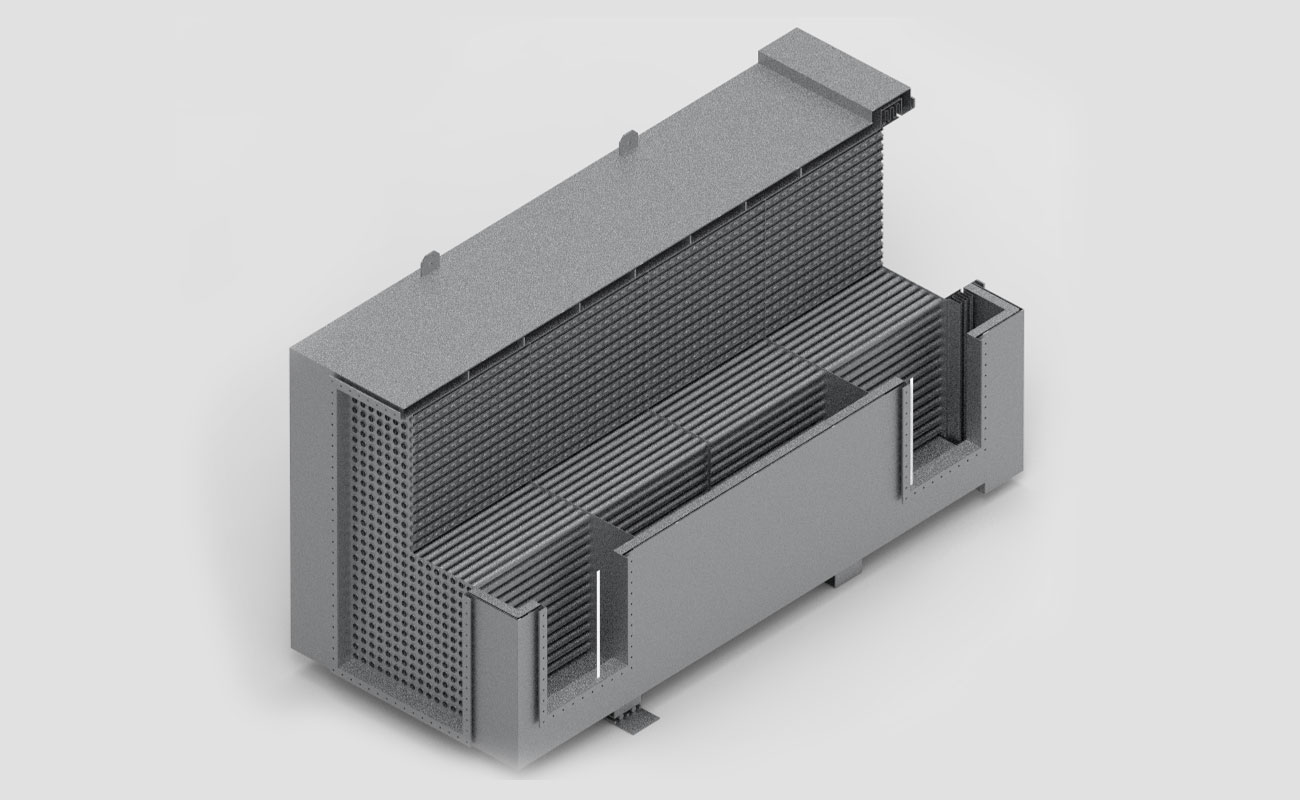

NEW HIGH EFFICIENCY JACKETED EXCHANGER

RELIABILITY

Mixed counterflow + parallel flow design

Maximum metal temperature up to 150ºC interior vs traditional counterflow exchangers

PERFORMANCE

Maximum air preheating temperature 800ºC

Operates continuously, monitored remotely

Used by leading companies in the sector

Fields of application

- Forging furnaces

- Frit melting

- Glass production

- Aluminium melting

Criteria for use

- Hot gas temperature > 1000ºC

- Gases that contain aggressive components or a large quantity of particles