Extend the life of your product performing at its best

Engineering, R&D, Manufacturing and SAT

Overhauling & updating

Commissioning and warranty

Preserving & maintaining

COMMISSIONING

The goal is to keep the equipment fine-tuned to guard against future problems.

We offer a maintenance service for the entire Kalfrisa product range. Maintenance is adapted to client and facility needs.

One of the added values of Kalfrisa is extensive experience in commissioning on the client's premises.

All this experience ensures a top-quality service and a reduction in problems that may arise during commissioning.

Training with the client takes place from the outset and continues through the initial use of the system, ensuring the machinery has the right parameters and works properly.

Commissioning of new Equipment

Electrical Installations

Electrical Connection | Control Panel

Commissioning of Burners

Fine-tuning of Old Equipment

Repair of electrical panels

PREVENTIVE MAINTENANCE

The goal is to keep the equipment fine-tuned to guard against future problems.

We offer a maintenance service for the entire Kalfrisa product range. Maintenance is adapted to client and facility needs.

Our extensively experienced technical team performs maintenance via planned routes. This means the client can choose among quarterly, bi-annual and annual checks.

Not only is the equipment reviewed and checked, the client is also advised on its condition and any future corrective or updating measures that can be undertaken to ensure the installation remains in ideal working conditions. Thus, we take all necessary steps to increase the service life of the equipment; in addition, there is the chance to add to the support on offer, with an on-call service also available.

Check paint, control of welds, greasing of parts, equipment cleanliness

Check inside the equipment

Inspection of heat resistance, fibres and ceramic bricks, equipment cleanliness

Check instruments and replace in case of breakage

Temperature, oxygen, servos, end of stroke probes

Inspection and cleaning of the engines

Inspection and measurement of the burners

Examination of the electrical panel

CORRECTIVE MEASURES

At Kalfrisa Service we can provide you with specific advice to solve all kinds of problems that may appear in your system.

We not only perform in-person interventions but also provide all kinds of remote help to solve your problem as quickly and efficiently as possible so you can continue working without further ado.

Our technical expertise results in specific quality repairs for our work sectors.

The objective is to have the equipment up and running in the best conditions possible.

Heat resistance repairs

Instrument repairs

Burner repairs or replacement

Fan repairs

Repair of electrical panels

Valve repair

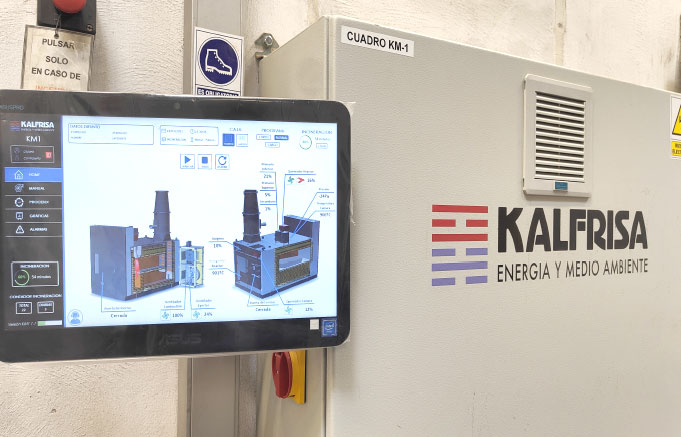

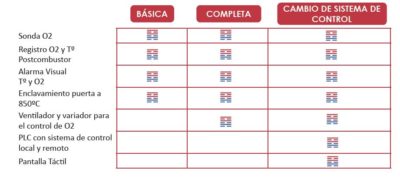

AUTOMATING EQUIPMENT

Kalfrisa is committed to keeping its equipment up to date, offering bleeding edge automation technology.

Due to the age of some machinery, and how long it has been installed, we offer the possibility of performing an update of your control system. This will see a change in programmable automaton so as to benefit from the very latest operating characteristics and connection possibilities.

UPDATING EQUIPMENT

Our commitment is to bring all the technological innovations to every one of our clients, either by means of new machinery or by adapting older systems to current regulations and technology. Due to the age of some machinery, and how long it has been installed, we offer the possibility of performing an update of your control system. This will see a change in programmable automaton so as to benefit from the very latest operating characteristics and connection possibilities.

The industry in general - and Kalfrisa in particular - is committed to digital and connected systems that allow the user to have real-time information about the status of their furnaces at any time and from anywhere.

View the furnace on devices via web (Android, Windows, IOS, etc.)

Remote connection via WiFi

Possible optional remote connection (if the client has Ethernet or a 4G modem)

Data recording on micro SD card inserted in PLC

Data logging on the connected remote devices.

Control servo times

View incineration times

Display temperatures

Display incineration status (heating, incinerating, cooling)

Control cooling times and incineration duration

AUDITS AND MEASUREMENTS

Over the years, public administrations have become more demanding regarding data that must be provided to comply with regulations and authorize the use of equipment. Kalfrisa has technical specialists in each sector of its commercial range to provide the finest service and offer the best solution to each client. Through a prior audit and corresponding sampling, we propose the best solution to our clients to adapt their systems to the current environmental requirements.

We perform in-person and online technical audits of the following sectors:

- Air generators.

- Disposal of Volatile Organic Compounds (VOCs).

- Waste recovery.

- Cremation furnaces for human and pet remains.

- Animal incinerators.

We also collaborate with the big OCAs, coordinating the measurements to have in-person or online support from a Kalfrisa technician, thus ensuring the best results.

FID ANALYZER

- Measurement of Total Organic Carbon Emissions (TOC)

- Measurement of CO emissions

- Measurement of NOx emissions

FLOW MEASUREMENT

- Measurement of the flow rate in a vacuum.

- Pitot Tube

- Relevant instrumentation

ANALYSIS OF COMBUSTION

- Oxygen Measurement

- Measurement of CO emissions

- Measurement of NO emissions

ADVICE AND CONSULTANCY

Do you have an old machine? Do you want to automate processes? Do you need to save on consumption? At Kalfrisa we can offer you the best advice and consultancy for your systems.

We provide innovative, specialised solutions to each client, employing a network of technical collaborators for each sector. This means we can provide the most solid and precise advice at every stage of the project.

Our extensive experience of the entire industrial process (design and engineering, manufacturing, commissioning and technical support service) allows us to undertake the studies and prepare the projects in the best possible way.

In addition, in all our preventive and corrective maintenance services, our technicians perform an initial visual inspection to propose areas for greater optimization.

- Optimization of how the system works.

- Process optimization.

- Consumption optimization.

Ensuring optimum performance

OUR ENGINEERING TEAM STUDIES THE NEEDS OF EACH PROJECT TO DESIGN THE MOST SUITABLE SOLUTION.

WE HANDLE ALL TRANSPORT, INSTALLATION, ASSEMBLY AND TRAINING TO ENSURE OPTIMUM OPERABILITY.

OUR TEAM CAN DO THE PREDICTIVE, PREVENTIVE AND CORRECTIVE MAINTENANCE OF THE INSTALLATION TO ENSURE MAXIMUM PERFORMANCE.

We are connected

Protocols for regular inspections, allowing for optimal functional continuity.

The Preventive Program covers the established check-up visits and priority attention to fault warnings, enabling rapid assessment of the latter.

Scheduled visits on routes throughout the country.

FAULT WARNINGS WITH DIAGNOSIS

ORIGINAL SPARE PARTS AND MATERIALS

ADDITIONAL 365 ON-CALL TELEPHONE SERVICE..

Remote support

...which gives us real-time knowledge of how your machinery is operating, vital for prevention and the focused attention of our experts

- Intuitive interface for the operator.

- Facilitates detection and diagnosis of components.

- Improved user management.

- Maintenance notification.

- Direct contact with Kalfrisa SAT.

- Access to the web to check spare parts or FAQs

- Modification of PLC program for adaptation

- Creation of new functions

- Enables the furnace to be operated from any device via Ethernet, WiFi or 4G

- Adapted to mobile devices.